Electromobility is advancing: battery factories are currently being built by various manufacturers. MVI PROPLANT is also involved in the construction of a gigafactory in the German state of Hesse right from the start. Head of Factory Services, Sven Klinkau, is responsible for the project, which MVI PROPLANT is implementing on behalf of MANZ AG for a manufacturer of vehicle battery systems.

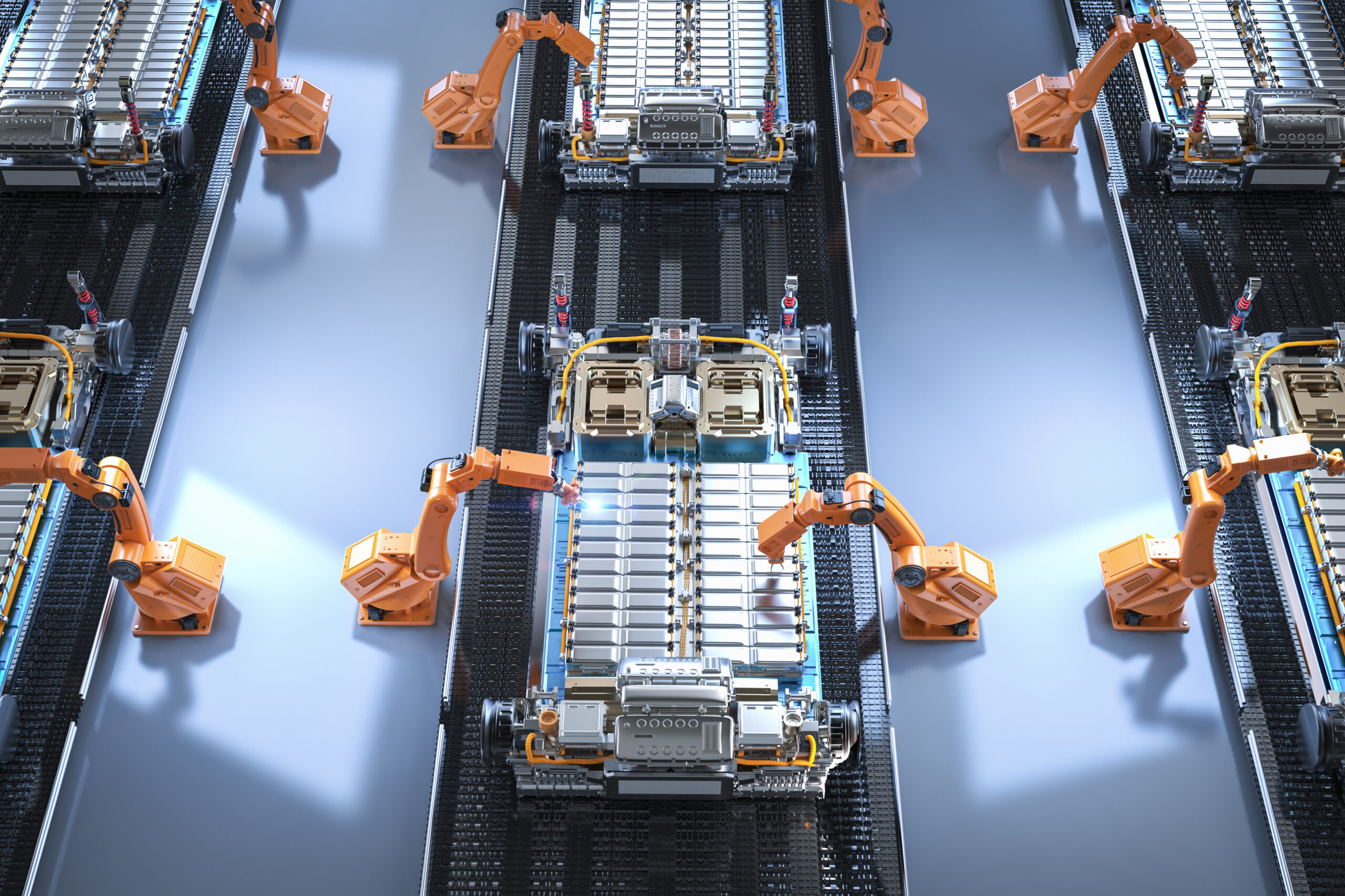

The mobility industry is increasingly going electric. Factories for the production of battery systems are being built all over the world. Since February 2021, a combined project team from MVI PROPLANT of different company units has been implementing the installation and commissioning of a production line for lithium-ion battery modules. “In the process, we mechanically and electrically set up an assembly line in a gigafactory,” Sven Klinkau recounts. “At peak times, we provided a team of about 30 people, consisting of site managers, engineers, mechanics and electricians from Stuttgart and Bratislava. In addition to the assembly services, we then took over the move-in of the equipment to the factory and set up 10 robots.” The experienced factory planner and manager already has a lot of expertise with the planning and implementation of BEV assembly lines, but setting up a pure battery manufacturing production is associated with other challenges.

Battery vs. vehicle assembly: what to look out for in planning

“Some of the technologies used in a Gigafactory were new to us, but it was also quite exciting to see the different assembly steps that are necessary.” For example, much more attention has to be paid to cooling options during planning. When insulating, the heavy battery module has to pass a special high-voltage test. “What was also new for me, for example, was the so-called plasma cleaning, which is needed for a higher strength of the glue to make the battery modules safer when gluing. Also that really every single AA battery goes through laser cleaning has to be considered in such an assembly line.” A battery module alone contains hundreds of these individual batteries, which are primarily intended for installation in buses and trucks.

For such a battery production to work, “our team worked in 3-shift operation from December 2021 to May 2022 during the start-up phase,” says Sven Klinkau. Since summer 2022, things have continued ambitiously: a second assembly line with additional battery types was made by the colleagues.

An international project: from Germany to the USA

Then it was off overseas. “There we designed an assembly line for battery production identical in construction to the one in Germany. The control was run from our Stuttgart MVI location. The implementation was done on site by the colleagues from the US location.” Sven Klinkau is pleased to be actively involved in the success of these projects. For MVI PROPLANT, it is an important major project in the Gigafactory environment. The learning effect has been enormous, so that MVI PROPLANT can also demonstrate comprehensive expertise in the development of battery production.

Do you have any questions or comments on the subject of setting up assembly lines or designing a gigafactory? Then please do not hesitate to contact us:

Sven-Klaus Klinkau / Head of Factory Services

Tel: +49 1520 2020 137

Mail: Sven-Klaus.Klinkau@proplant-mvi.com